Introduction

In today's packaging and printing industry, choosing the right duplex board with white back is crucial to product quality. As environmental standards rise and printing technologies evolve, the 2025 market for white back duplex board is seeing many new developments. This guide will explain the key features of this material and offer practical tips to help packaging buyers like you make smart purchasing decisions.

The Features of Duplex Board With White Back

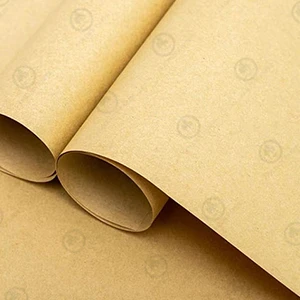

White back duplex board is a specialty paperboard made with a three-layer structure. The top layer is crafted from bleached chemical wood pulp, offering a brightness level of over 90%. The middle layer consists of mechanical pulp, giving the board its thickness and stiffness. The bottom layer is made from grey recycled fiber, which provides flatness and stability to the sheet.

Factors to Consider When Choosing Duplex Board With White Back

The Grammage of Duplex Board With White Back

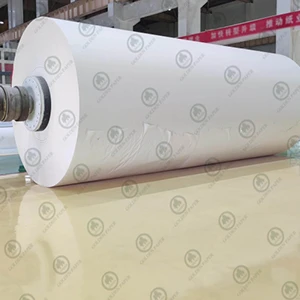

First, you should consider the relationship between grammage (weight per square meter) and board thickness. Common duplex board grammage ranges from 250 to 400 gsm. In production, thickness tolerance should be tightly controlled within ±5%. Lighter grades like 250–300 gsm are ideal for color boxes and shopping bags, while heavier grades (350–400 gsm) are better suited for premium gift boxes and hardcover book covers, providing enhanced strength and support.

The Surface Properties of Duplex Board With White Back

Next, pay close attention to surface properties. A qualified white back duplex board should have a smoothness of over 200 seconds (Bekk method). For gloss, it's recommended to choose a board in the 35–60 GU range. If your packaging involves printed text or graphics, be sure to check the board's ink absorbency—an ideal K&N value is between 18 and 23.

The Printability of Duplex Board With White Back

Printability is another key factor. If you plan to use offset printing, the board should deliver a dot reproduction rate of at least 95%. For products requiring foil stamping, the coating uniformity is critical. In practical printing, color difference (ΔE value) should be kept below 2.0 to ensure consistent print quality.

The Physical Strength of Duplex Board With White Back

Physical strength is equally important. For example, a 350 gsm duplex board should achieve a bursting strength of at least 400 kPa. Longitudinal stiffness should not fall below 7.0 mN·m, and internal bond strength should exceed 180 J/㎡.

Eco-Friendly Compliance

Lastly, consider environmental compliance. The duplex board you select must meet GB/T 35601-2017 food safety standards and comply with EU 10/2011 regulations on heavy metals. We recommend choosing products with FSC Mix certification, which ensures stronger environmental protection and sustainable sourcing.

Solutions to Common Problems

In practice, you may encounter issues like warping after printing. To prevent this, choose boards with a moisture content around 6%, allowing a tolerance of ±1%. If you experience cracking during die-cutting, check the folding endurance—qualified boards should withstand at least 50 folding cycles. For color variance problems, ask your supplier to provide color inspection reports based on standard light sources.

Conclusion

When selecting duplex board with white back, it is best to first request samples for testing and carefully review quality inspection reports. Prioritize suppliers with ISO 9001 and FSC certifications for reliable quality. At Golden Paper, we offer a full range of white back duplex boards from 250 to 400 gsm, all FSC-certified and customizable with optional slitting and special coatings. We maintain strong inventory levels to support fast delivery. To learn more about our products, visit the Golden Paper website to consult with us and download our latest technical data sheets.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id