Introduction

If you're sourcing paper products for your business or factory, you've probably come across the term pulp. But what is pulp? As the raw material used to make paper, understanding pulp and how it works can help you make better decisions when buying paper. Keep reading — in this article, we'll explain what pulp is, the types of pulp, where pulp comes from, and why it matters.

What Is Pulp in Paper?

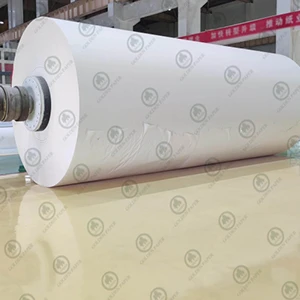

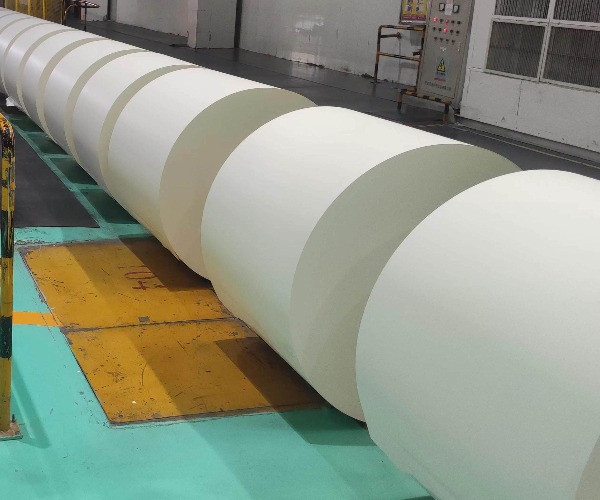

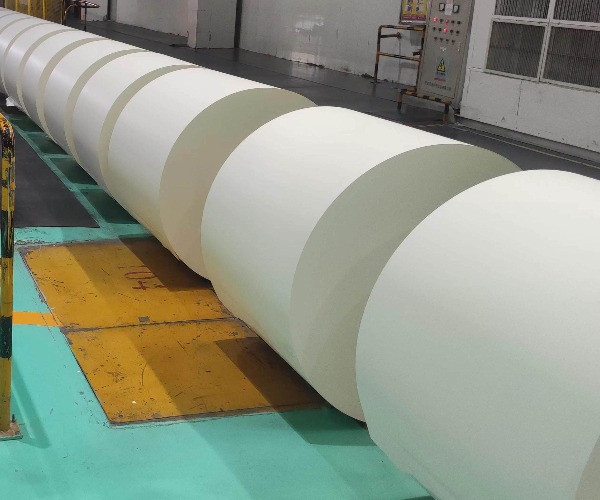

Pulp is the raw material used in papermaking. At our paper mills, pulp is made by processing plant fibers -usually wood, but also bamboo and grasses — into a fibrous material. This material can then be used to make various types of paper. Understanding pulp helps you choose the right kind of paper, whether it's for printing, packaging, or specialty applications.

Types of Pulps

As a paper buyer, it's important to know about the different types of pulp available because pulp quality affects the paper's performance. For example, wood pulp has longer fibers and stronger bonding strength. It also creates less dust during processing. In contrast, grass pulp has shorter fibers and weaker bonding, which may produce more dust during processing — potentially harming workers' health. Pulp can be categorized in two ways. By raw material: virgin wood pulp, recycled pulp, and mixed pulp; By processing method: mechanical pulp, chemical pulp, and semi-chemical pulp

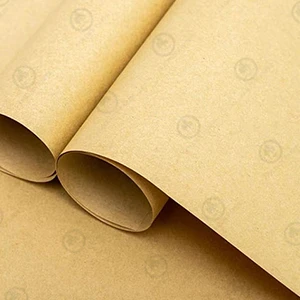

Virgin Wood Pulp

Virgin wood pulp is made from raw wood and includes mechanical, chemical, and semi-chemical pulps.

Mechanical pulp is made by grinding wood. It retains most of the lignin and separates fibers using physical force.

Chemical pulp is produced using chemicals under high temperature and pressure to remove lignin and dissolve hemicellulose, resulting in cleaner fibers.

Semi-chemical pulp combines physical grinding and chemical cooking to break down the material.

Recycled Pulp

Recycled pulp is usually made from wastepaper, though it can also come from offcuts and trimmings produced during paper conversion. If your business values sustainability, this is an excellent choice. A strong eco-friendly image can help your brand earn more trust and support in the market.

At Golden Paper, we help you select the right pulp-based paper products based on your specific needs—whether you need high-brightness printing paper or food-safe packaging board.

Why Pulp Is Important

Why does pulp matter so much in papermaking? Because the quality of the pulp directly affects how the paper performs. High-quality pulp means better printability, higher strength and durability, a brighter and more uniform appearance, and better suitability for specific uses like food packaging or high-speed printing.

Why Should You Consider the Pulp of Paper?

Different pulps create different types of paper. Choosing the right pulp can reduce waste during production, lower customer complaints, and help your printing machines run more smoothly. It also reduces wear and tear on your equipment. Plus, if surface finish is not a top priority for you, using paper made from recycled pulp can help cut your long-term costs.

Conclusion

Golden Paper offers premium paper and paperboard products made from 100% virgin wood pulp, including office paper, industrial packaging paper, printing paper, and food-grade boards. We understand that choosing the right paper is critical to your production line. That's why we're committed to delivering consistent quality, reliable performance, and high value.

Contact us today and partner with Golden Paper for your paper solution needs!

FAQ

Why choose recycled pulp?

Recycled pulp helps reduce environmental impact and production costs. It’s a great choice for businesses focused on sustainability.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id